Water behaviour in drying concrete determined by EIS-100 using impedance function |Z|

The evaporation of water from the drying concrete causes changes in the impedance loss factor, which is reflected in the real and imaginary parts of the impedance. Particularly demanding monitoring of the drying of the concrete turns out to be the case with the casting of the tiles, where the water can only be damaged by one surface. The situation has been simulated under laboratory conditions by drying the concrete casting in a plastic container, whereby the removal of water from the concrete that is drying out occurs only through one surface (cf. figure).

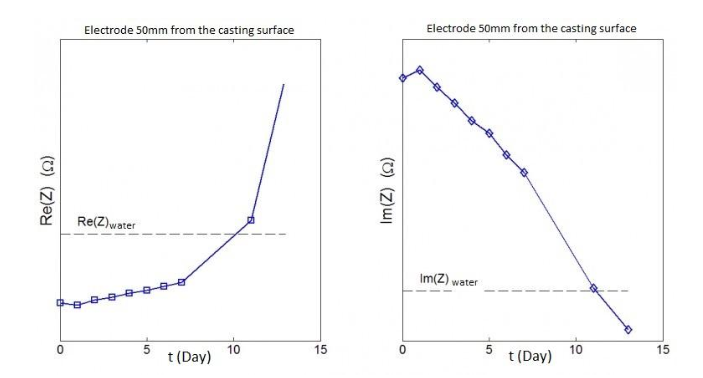

The above two figures show a graph of the drying of the concrete, determined by the EIS device, when one sensor is placed close to the concrete casting surface (50 mm from the surface) and the other to a depth of 140 mm to the concrete. The impedance responses produced by the device can be used to determine the time estimates required for the drying of concrete. The time determination can be done using either the impedance (Z) resistance Re (Z) or its reactance Im (Z). When the impedance resistance part is used, the wet concrete mass contains more ions than the water used in its manufacture, which affects the loss factor and consequently the wet concrete resistance portion is smaller than the water resistance portion indicated by dashed lines. As the concrete dries, the relationship between them begins to decrease and eventually the parts change. By projecting this intersection on the time axis (elapsed time in days), a time estimate is obtained for the drying rate of the concrete. The impedance reactance portion measured from wet concrete behaves inversely compared to its resistance portion. For the rest, the situation is as described above. Estimated time of drying of the concrete at each of the intersection points has been found to correspond well.

[/fusion_builder_column]

The matter has been gravimetrically verified by monitoring the weight change of concrete casting. The weight of concrete in the plastic container (1.51 kg of water and 11.79 kg of total weight) will only be reduced by 24.6% in 24 days, although the change should be 79.2%. Thus, the dried surface layer having a surface moisture of 1.4% after 11 days, 1.0% at 17 days and 0.6% at 24 days slows down the evaporation of water.

[/fusion_builder_column]

[/fusion_builder_column][/fusion_builder_row][/fusion_builder_container]